Contact: Mr. Roy Dong

Mobile: +86-13455012133

Fax: +86-0633-7777977

Website: http://www.hhpof.com/eng

Online Store: https://huihehuanbao.1688.com/

News

Contact Way

Latest News

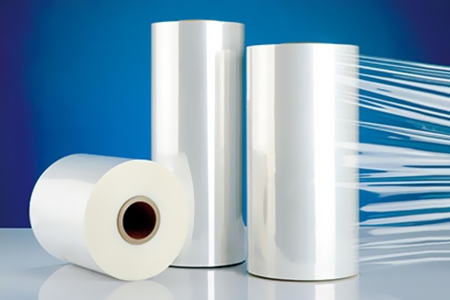

The packaging film of instant noodles is made of blow molding and casting.

1. Blow molding method

Through direct contact of water with the surface of the film, it can be cooled quickly and stretched spherically. The flatness is slightly less than the extension method, but the transparency is better. At the same time, spherical stretch film has further influence on the ductility of food high barrier stretch film.

2, the extension method

After cooling roll cooling, food high barrier stretch film has a specific longitudinal stretch, no transverse stretch, the overall flatness is good, transparency is lower than blow molding, but the stretching ductility is better.

The 11-layer film co-extrusion process is adopted, and the 11-layer film structure is co-extrusion once. After forming, it flows down like a waterfall. After cooling by cold water roller, the plastic film is formed. Because the instant noodle packaging film itself has not been stretched, it has good malleability. It is an ideal stretcher for forming stretch film, suitable for batch packaging. Compared with the traditional vacuum pump, saving manpower, high efficiency.

Because the main objects of food packaging film are diverse and have different requirements, the content of packaging basically covers the range of composite packaging bags, from raw to cooked, from low temperature to high temperature, from perishable fresh fruits to hard nuts, from vacuum packaging bags to inflatable packaging bags.

(1) Separation requirements: most foods are rich in oil and are easy to oxidize and deteriorate. So they have strict requirements for oxygen resistance, and they also have high requirements for the increase or decrease of moisture in food packaging film.

(2) Water activity: All foods contain a specific amount of water. After the selection of packaging materials, the moisture content of food changes little if the processing conditions and formula of food remain unchanged. When conditions change, it will directly affect the original water activity value of food, and water is one of the important factors causing food deterioration. Microbes can grow as long as they have a specific water content. Different materials and methods should be used for different foods with different water content.

(3) Vacuum requirements: vacuum packaging is isolated from oxygen and moisture-proof, which can not only ensure the quality of materials, but also make the appearance of goods beautiful and generous.